Compact Design

- Modern look.

- Small size for easy installation.

- Custom finishing.

- Module width only 590 mm (approx. 23.25").

- Can be installed in confined spaces.

MYSTIQ is capable of burning a wide range of biomass fuels, including wood and biomass-waste pellets.

Heat output can be controlled in the range from 7 to 25 kW for all guaranteed fuels.

High combustion efficiency of 94% and automatic adaptation to the fuel used.

The only automatic vacuum boiler featuring two-stage combustion.

Multiple linked units provide a heat output of up to 100 kW, capable of automatically heating your house or larger commercial building.

Requires no manual handling or cleaning.

Remote control capability.

Features IoT functions.

Biomass stores the power of the Sun, making it a cheap, locally available, renewable and virtually endless energy source. Moreover, combustion of biomass pellets in the MYSTIQ system produces pure minerals with a very low sulphur content capable of being used as high-quality fertilizer. The amount of carbon dioxide (CO2) released into the air during combustion is the same as the plants consume through photosynthesis during their growth. Water and carbon neutrality is reached already in a one-year cycle.

Low emissions

for a clean environment.

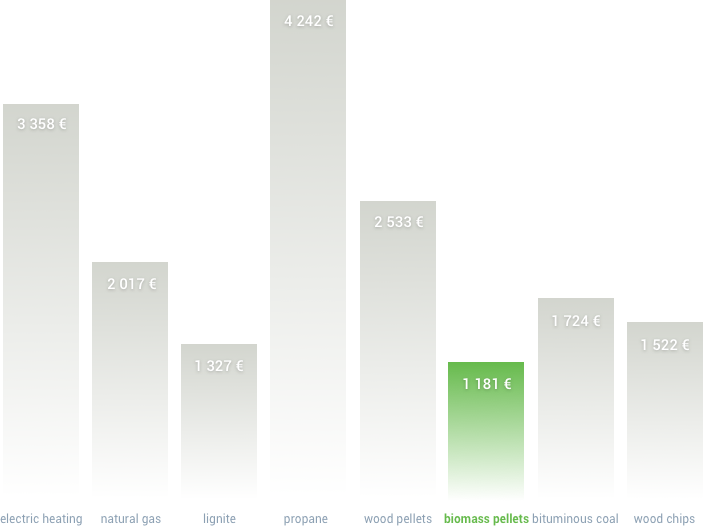

MYSTIQ is an extremely cost-efficient heating solution, allowing all owners of typical older uninsulated homes to save at least 12% of their previous heating costs regardless of the heating system currently used. Our fuel prices are guaranteed for 5 years in advance. *Source: TZB info, price adjustments 10/2017

Buying a heating system is just the beginning. When selling a heating boiler we reserve for each customer enough fuel for one full heating season (typically 5 to 10 tonnes per property). We make the biomass pellets ourselves.

“I wanted to take my time when choosing the right heating boiler for me – after all, it will keep our home warm for many years to come. The requirements were always clear: fuel, heat output, efficiency, consumption and price. MYSTIQ uses state-of-the-art technology that puts it way ahead of the game, making it a future-proof solution to be reckoned with.„

MYSTIQ was conceived and designed in the Czech Republic. The system's origins date back to when its future designer studied combustion engines at Brno University of Technology. His deep interest in the Stirling and external combustion engines gradually led him to what eventually became a brand new heating system. The journey started with getting to know the fuel and its properties. This knowledge allowed the team to design a device respecting the peculiarities of biomass combustion.

First prototype released

Long-term test: 1000 hours of continuous operation

Upgraded grate with micro-feed capability

Deployment of the Foxtrot PLC

Switch to a wide band lambda sensor

Development of our own ignition system with 50% energy savings

Combustion kinetics improved to 96% efficiency

Development of our own control board

Switch to flat transmissions with stepper motors

Improved self-cleaning grate bar edges

Upgraded generator

Improved user interface

New corporate identity and website

We are finishing the last preparations for series production.